July 13, 2019

The Union Pacific 4000-series locomotive (known as the Big Boy) was built in the years 1941 through 1944. It was the largest and most powerful steam locomotive ever operated by the Union Pacific. Twenty-five were built for the heavy freight traffic over the Wasatch Mountains.

For the commemoration of the 150th anniversary of the completion of the transcontinental railroad, Union Pacific has restored one of these engines (#4014). The first trip after the restoration was from Cheyenne Wyoming to Ogden, Utah. The second trip is to be a grand tour of the mid-west including Chicago, Illinois and Duluth, Minnesota. The first major stop as it rolled east from Cheyenne was Omaha, Nebraska--these are photographs of that stop.

View the train on November 21 rolling through Wilson, Kansas here.

Nebraska

Nebraska

The evening of July 12, the engine slowly rolled to the end-of-the-tracks at the "Home Plate" location in Omaha. Historically, this is where the transcontinental railroad began (on the eastern end).

Big hardly describes it. The thing is overwhelming.

This engine represents the pinnacle of large steam engine design. Diesel-electric locomotives were already here, but at least for the time, the Big Boy was--by far--the more capable.

It's not likely that any of the working locomotives from the 1940s and 1950s ever looked this clean, but then, this restoration might be the finest of all the 4000-series engines. If parts were not considered adequate, they were re-manufactured. As any of the restoration crew would say "good enough is not acceptable." Their locomotive was a restoration for the years to come.

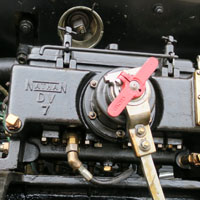

Throughout, the design details showed really innovative thinking. This is an efficient machine.

The chalk-writing on the boiler matches the first engine, when an employee wrote those words as it was delivered from the factory in Schenectady, New York.

It's an articulated engine, which means there are effectively two engines under that long boiler, and these two engines (each with eight driving wheels and two pistons) must be able to follow the track independently of the other. That means the high-pressure steam line (300 psi) must also have flexible connections.

Pure function: no pointless streamlining, nothing covered up, no embellishments.

There was a good crowd that came to see #4014, the next day.

The whole crew (being the same folks who did the rebuild in Cheyenne) were really helpful answering questions. You could tell the pride they had in what they had accomplished.